MKS INSTRUMENTS MECHANICAL/ELECTRICAL ENGINEERING INTERNSHIP.

GASKET PROJECT.

Client:

ME360 Assignment

Location:

Boston University, MA

Date:

5/23/23 – 5/31/23

Programs Used:

SolidWorks

GibbsCAM

FlashPrint

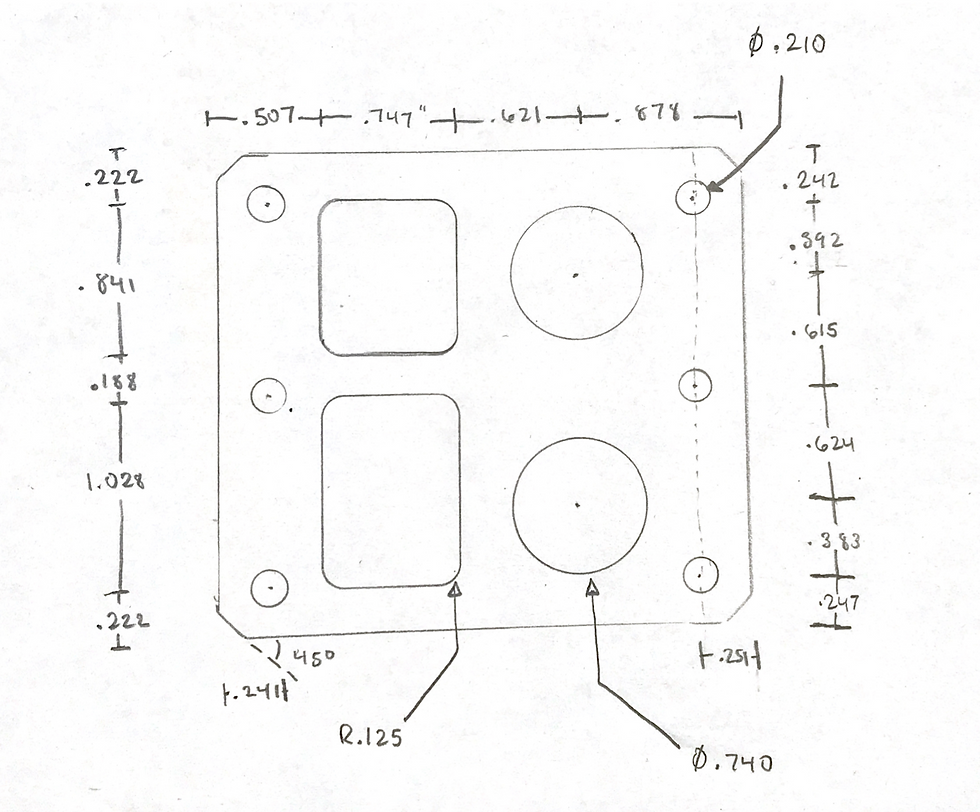

The task was to design a 1/16" gasket for a specified aluminium block with unique features. These features include hole and square cutouts of unspecified locations and dimensions on the block. There were also two central pins used for centering the gasket to the aluminium block with four 10-32 thread screw holes at the four corners. Using a caliper, measurements were taken of the aluminum block and were converted into a CAD model. From here, the inverse shape became the gasket to be converted into G-Code to be CNC milled.

Fitting the gasket onto the aluminium block, the screw and pin holes matched perfectly and the cutouts matched the block. However, the holes for the four corner pins were tight for the 3D-printed model, likely due to the tolerances being too tight. Thus, on a second print, I would enlarge the diameters by roughly 0.3mm for a better fit.

Assembled Gaskets

PVC Gasket (top view)

Dimension Sketch (hand draw)

Assembled Gaskets